The Power of Public Art

Public art is infrastructure for the imagination. In 2025, the pathway from concept to crane day is clearer—and faster—than ever. As a foundry member of CODAworx, American Fine Arts (AFA) helps artists, architects, and cities move from spark to steel with a proven, end-to-end process: win the opportunity, engineer the vision, fabricate with excellence, and install with confidence.

Why CODAworx + AFA now

More, better opportunities. CODAworx maintains a live directory of public-art RFPs—across budgets, materials, and sites—so you can target projects that fit your practice. opens in a new windowCODAworx

Community and deal-flow. CODAsummit 2025 (Washington, DC, Sept 24–26) convenes decision-makers across art, tech, and place—prime ground for relationships that lead to commissions. opens in a new windowCODAworx opens in a new windowHubSpot opens in a new windowInstagram

A foundry built for monumental. AFA’s digital-to-bronze pipeline (ZBrush → mold → casting → patina) and public-art fabrication services shorten timelines while protecting the artist’s intent. opens in a new windowAFA Foundry

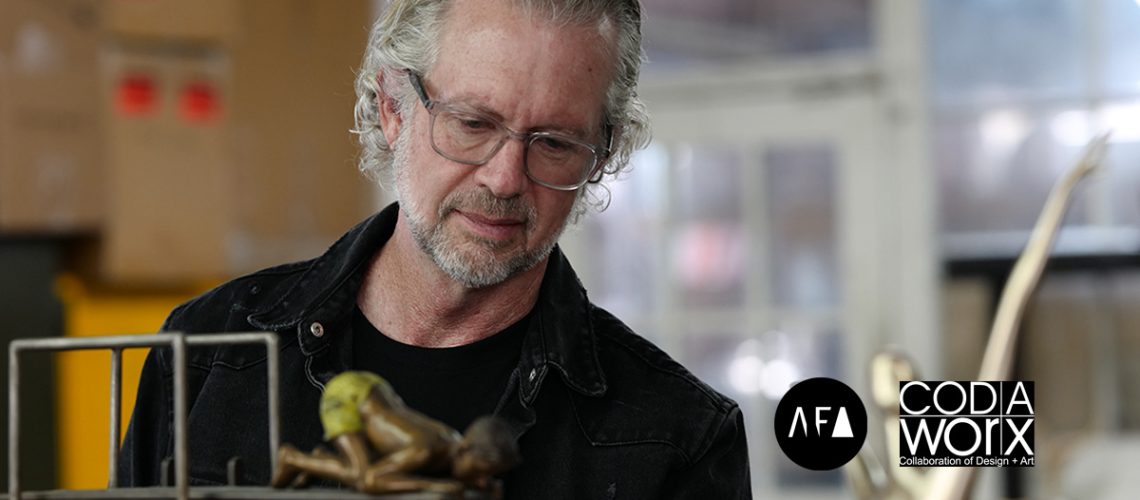

Leadership you can trust. Our Chief Collaborator, Brett Barney, coordinates artists, engineers, and installers with a calm, expert hand—exactly what complex public art requires. opens in a new windowAFA Foundry

The 7-Step AFA × CODAworx Pathway (2025 Edition)

1) Scan & select the right RFP

Start at CODAworx Open Calls. Filter by budget, medium, and timeline. Track deadlines. Shortlist three that align with your portfolio and site experience. opens in a new windowCODAworx

2) Craft a win-worthy proposal

Lead with a clear story of place impact (community, wayfinding, identity). Pair renderings with a high-level schedule, risk plan, and letters of support. When available, leverage CODAworx programs (e.g., Emerging Artist) to expand eligibility and visibility. opens in a new windowCODAworx

3) Translate concept → constructible

Upon shortlist/award, we help you move from mood boards to working drawings: exploded views, material specifications (bronze, stainless, mixed media), anchoring details, finish schedules, and maintenance notes. This is where we align art intent with budget and municipal requirements.

4) Build the maquette & digital twin

A physical maquette plus a clean digital model accelerates approvals and engineering. Our team routinely converts ZBrush (or comparable) sculpts into foundry-ready geometry, anticipating gating, shrink, and assembly. opens in a new windowAFA Foundry

5) Engineer for the real world

We coordinate with your structural partners (or introduce ours) to validate bases, wind/seismic loads, access/ADA touchpoints, and installation sequencing—reducing surprises during permitting and crane day.

6) Fabricate with excellence

From mold to pour to patina, AFA’s artisans execute to spec. We combine traditional craft with modern QA: pattern checks, wax gating logic, metal integrity inspections, weld mapping, surface finishing, and patina control—delivering museum-grade results at civic scale. opens in a new windowAFA Foundry

7) Install & handoff

We plan rigging, crate design, site logistics, and punch-list management. Close with a care & maintenance package for your client, plus documentation that supports future conservation.

2025 Opportunities Snapshot

Active Open Calls: Browse current RFPs (multi-disciplinary; varied budgets/qualifications) on CODAworx. opens in a new windowCODAworx

Regional Examples: Municipalities across the U.S. continue to release new public-art RFPs (e.g., Dallas Design District trailhead; multiple city/county programs). opens in a new windowCODAworx opens in a new windowGlasstire opens in a new windowPalm Beach County

Network at CODAsummit: Meet commissioners, fabricators, and technologists in D.C., Sept 24–26, 2025. opens in a new windowCODAworx opens in a new windowHubSpot

Work with AFA: What to Send for a Fast Quote

- A brief: site, intent, target budget, and timeline

- Drawings or a model (even early)

- Preferred material/finish (e.g., bronze with patina, stainless, mixed media)

- Any engineering constraints known to date

Our team—led by Chief Collaborator Brett Barney—will map the route from where you are to a safe, spectacular install, then price the options so you can choose with clarity. opens in a new windowAFA Foundry