American Fine Arts Foundry

It is an art and a science

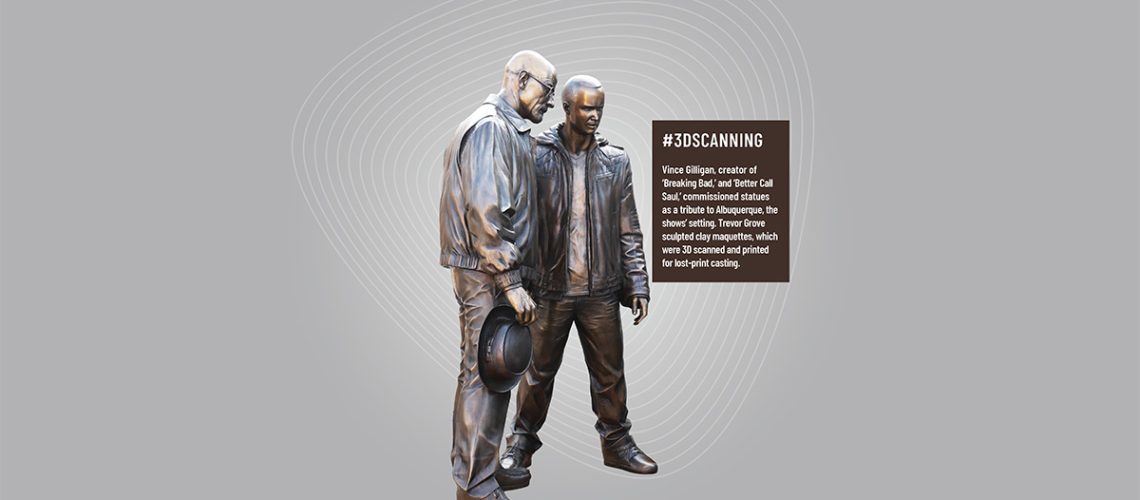

In the realm of sculpture, the transition from clay to bronze is an alchemy of art and science, a process beautifully orchestrated by the American Fine Arts Foundry (AFAF). This artistic journey was recently spotlighted through the commission of statues by Vince Gilligan, the creative genius behind ‘Breaking Bad’ and ‘Better Call Saul’, as a homage to Albuquerque, the heart and setting of these iconic shows. The task of bringing these tributes to life fell to the talented hands of sculptor Trevor Grove, who meticulously sculpted clay maquettes of the characters. However, the real magic began when these sculptures were prepared for bronze casting, a process enhanced by modern technology through 3D scanning.

The Process of 3D Scanning

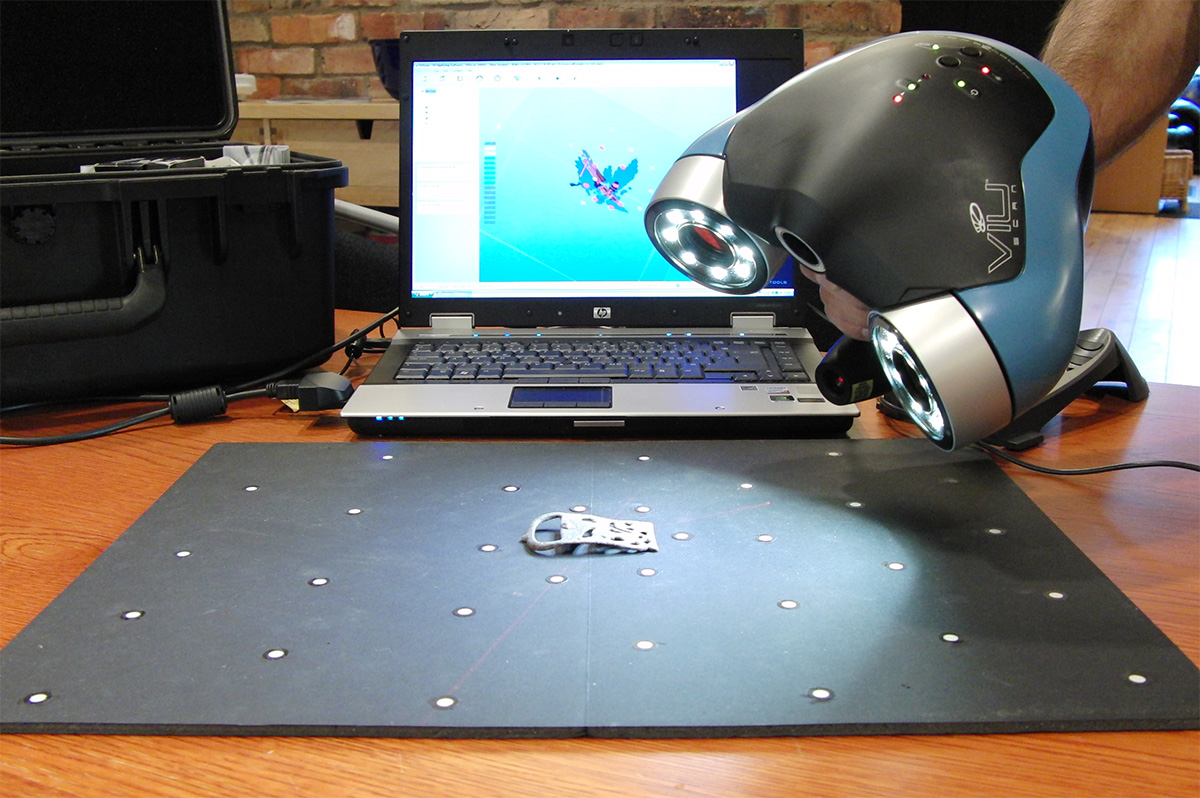

3D scanning is a technological marvel that captures the physical world into digital realms, enabling artists and foundries to work with incredible precision and flexibility. The process starts with a physical object, in this case, the clay maquettes sculpted by Grove. These sculptures are then subjected to a 3D scanner, which uses lasers or structured light to capture every nuance, texture, and detail of the surface. This digital capture creates a highly accurate 3D model of the original sculpture, which can then be manipulated, resized, and prepared for the next stages of the casting process.

Scaling for Bronze Casting

Once the detailed 3D model is captured, it can be scaled up or down according to the project’s requirements. For the ‘Breaking Bad’ tributes, the digital models allowed for precise scaling to ensure that the final bronze statues would resonate with the grandeur and presence intended for public display. This scalability is a significant advantage of 3D scanning, allowing artists and foundries to work in a range of sizes without losing any detail from the original sculpture.

Preparation for Lost-Wax Casting

The scaled-up digital model is then used to 3D print a replica of the original sculpture. This replica is created using a material suitable for the lost-wax casting process, a traditional method used for bronze sculptures. In lost-wax casting, the 3D printed model is encased in a ceramic shell, which is heated to remove the wax, leaving a hollow form. Molten bronze is poured into this hollow space, creating a detailed bronze casting after cooling and shell removal. The precision of the 3D model ensures that every detail from the original clay maquette is preserved in the final bronze sculpture.

Finishing Touches

After casting, the bronze sculptures undergo meticulous finishing work, including sandblasting, polishing, and patination. This work accentuates the details, textures, and nuances captured during the 3D scanning process, bringing the sculptures to life. The result is a stunning tribute that not only celebrates the characters and stories of ‘Breaking Bad’ and ‘Better Call Saul’ but also showcases the blend of traditional craftsmanship and modern technology.

🎯Blending Tradition and Innovation: The Journey of ‘Breaking Bad’ Statues from Clay to Bronze

The commissioning of the ‘Breaking Bad’ statues by Vince Gilligan highlights a fascinating blend of artistry and innovation. From the skilled hands of Trevor Grove to the technological prowess of 3D scanning and bronze casting at the American Fine Arts Foundry, this process embodies the evolving landscape of sculpture and public art. By embracing modern technology like 3D scanning, artists and foundries can push the boundaries of creativity, making the impossible possible and leaving a lasting legacy for generations to admire.

Yes! I want to talk!

About my bronze casting, stainless steel art project, art restoration or installation project.

American Fine Arts is the best bronze casting foundry